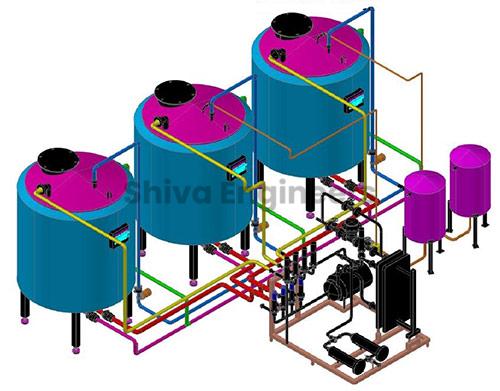

CIP System

CIP System Manufacturers in India and Suppliers in India

Shiva Engineers is a Specialized CIP System Manufacturers in India, also trusted suppliers and dealers in India. We supplying high-performance CIP (Clean-In-Place) systems to food, beverage, dairy, and processing industries. Our systems are also highly designed to provide uniform cleaning, maximum use of the chemicals and total elimination of contamination to enable industries to maintain a high level of sanitation and improve efficiency, operational or not.

Working Process of CIP System

As well-known CIP System manufacturers in India, the system operates by sequentially rinsing, washing, and sanitizing pipelines and tanks for complete hygiene.

- Pre-Rinse Stage: Primary flushing using water provides rearrangement of loose materials within the system and sets up the system with an efficient chemical cleaning capacity.

- Chemical Wash Stage: Specialized cleaning agents are pumped in controlled temperatures to dissolve fats, proteins and residues of all surfaces.

- Intermediate Rinse Stage: Extensive water rinsing guarantees the elimination of the traces of chemicals, avoiding cross-contamination.

- Sanitization Stage: The system is sterilized by sanitizing agents or steam killing all bacteria, yeast, and other microorganisms.

- Final Rinse Stage: Last water rinse ascertains the system to be devoid of chemicals and to be ready to manufacture without a chance of contamination.

- Drying & Inspection Stage: Dry hot air or nitrogen optional drying ensures the pipelines are dry, after which they are checked to confirm safety.

Types of CIP System

- Centralized CIP System: One large scale system supplies cleaning solutions to several processing lines within the plant, maintaining homogeneous hygiene and maximizing resource utilization.

- Distributed CIP System: Smaller, dedicated units are installed for specific sections or equipment, offering targeted cleaning, flexibility, and reduced downtime for individual lines.

- Mobile CIP System: Portable, compact systems allow cleaning of various equipment or remote production areas, ideal for small-scale operations or facilities with changing layouts.

Specifications of CIP System

As specialized CIP System suppliers in India, our systems feature PLC automation, corrosion-resistant piping, and hygienic design.

| Specification | Details |

|---|---|

| Materials | Contact parts: AISI 316L stainless steel, Non-contact parts: AISI 304 stainless steel, polished surfaces (≤0.8Ra) for hygiene |

| Flow Rate | 1 – 50 m³/hr (adjustable per process requirements) |

| Tank Capacity | 100L – 5000L+ (for caustic, rinse, and water tanks) |

| Pump Capacity | Centrifugal pumps designed to achieve 5–7 ft/sec fluid velocity in process lines |

| Operating Pressure | 3 – 6 bar (sufficient to overcome line friction and backpressure) |

| Temperature Range | Up to 90–100°C using electric or steam heaters for effective sanitization |

| Automation | Manual, Semi-Auto, Fully Auto (PLC) |

| Key Components | Tanks, Pumps, Heaters, Dosing, Sensors, Valves, Control Panel |

Key Features of CIP System

- Modular and Scalable Design: Can be set up for small, medium, or large processing lines, offering future flexibility.

- Real-Time Monitoring and Diagnostics: On-board sensors provide temperature, pressure, and chemical concentration data for visual confirmation.

- Automated Control Interface: PLC control allows cleaning cycles to be programmed, limiting human intervention and mistakes.

- Energy and Water Efficiency: Optimized irrigation and recycling of cleaning agents save power and water.

- High-Temperature and Chemical Resistance: SS304/316 grade components tolerate corrosive chemicals and extreme temperatures.

Applications of CIP System

- Beverage Industry: Ensures bottling and processing lines are clean to avoid microbial contamination of juices, soft drinks, and alcoholic beverages.

- Dairy Industry: Keeps pipelines, tanks, and pasteurizers clean, ensuring product purity and longer shelf life.

- Chemical Industry: Automatic CIP Cleaning System removes residues from chemical reactors and pipelines, avoiding cross-contamination.

- Pharmaceutical Industry: Ensures sterility of reactors, storage tanks, and filling lines, meeting GMP standards.

- Food Processing Industry: Eliminates residues in sauces, soups, and ready-prepared product lines, ensuring maximum hygiene.

Why Choose Us?

- Custom-Tailored Solutions: Each system is designed to suit your processing lines with the most efficient and sanitary approach.

- Industry-Leading Expertise: We have the experience to provide high-performance, highly-reliable CIP solutions tailored to clients.

- State-of-the-art Technology Incorporation: We integrate the latest automation, monitoring, and control systems to achieve accuracy, repeatability, and optimal performance.

Shiva Engineers is reliable CIP System manufacturers in India, suppliers and exporters in India. Our automation, precision engineering, and eco-conscious technology ensure that no contaminants are found in any pipeline or equipment, optimizing productivity and compliance. We are dedicated to reinventing industrial hygiene with our high-tech CIP Systems. Our solutions not only ensure new standards of sanitation but also enable industries to perform at sustainable, efficient, and reliable levels, making us a trusted partner in modern processing excellence. Get in touch with us for the best solutions.

FAQ’s

Yes, the CIP Systems of good quality are manufactured using stainless steel (SS304/316) which is resistant to corrosion and are capable of pumping strong chemicals and hot water safely to ensure successful cleaning of items.

A CIP System (Clean-in-Place) is an automated system which makes the cleaning of pipelines, tanks, and equipment in various industries possible without the need for their disassembly for hygiene maintenance. It is essentially the mainstay that keeps the products of these industries safe and of high quality.

Absolutely. We offer modular and scalable systems that integrate into any new or existing processing lines without interfering with production.